The most used woods for the production of frames are: Ayous, Pino, Abete, Ramin, Kotò, Jelutong, Tiglio and Frassino.

Ayous

Sometimes it is also called "obeche" or Samba or Wawa. It is a light yellow colored wood, soft and light without veins.

The ayous trees grow in the rain forests of West and Central Africa: Cameroon, Ivory Coast, Ghana and Nigeria, Gabon, Liberia, Sierra Leone, Central African Republic and Republic of Congo.

|

|

The tree reaches the height of 45-50 m. The trunk can reach 2 meters in diameter. For the first 30 meters it does not emit branches, which means that the wood obtained from it is free from knots.

All operations are easy: drying, sawing, peeling, hot air drying, vaporization, impregnation lead to discrete results. Because of its resistance to heat and humidity and its lightness and the absence of knots, ayous wood is used in plywood, in woodworking for packaging, in the manufactoring of kitchen furniture, in picture frames, in saunas, in violin making and bricolage.

It is imported into Europe already sawn in tables of standard thicknesses and standard length of about 3 meters.

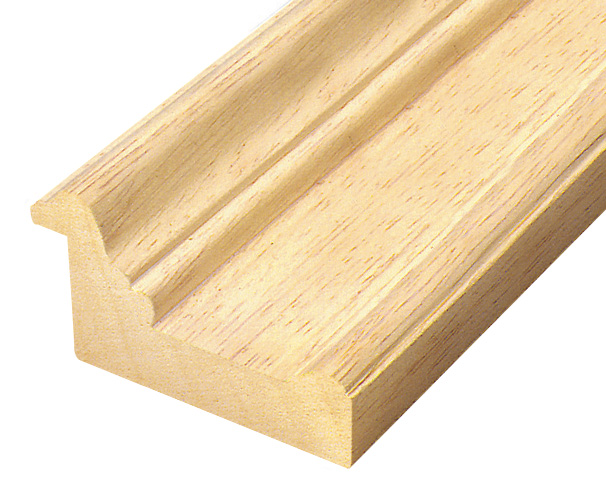

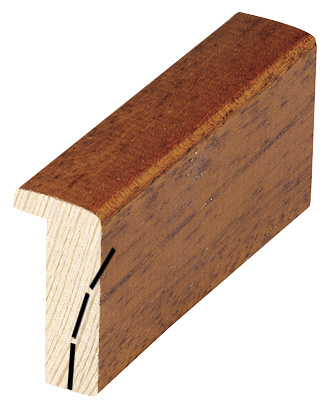

Moulding made of ayous wood

Being very soft it has a low rigidity. If the frame is very thin and large (for example 60 x 80 cm) it tends to "embark" for the weight when it is hung on the wall.

The ayous, therefore, is more suitable for thick mouldings with a thickness of at least 3 cm.

Its main flaw is that it is attacked by woodworms. This occurs more frequently in hot areas (for example Southern Europe, Africa, Middle East, Central America).

The woodworm (Anobium punctatum)

You can subject the ayous to a woodworm treatment before being used to make the mouldings.

The problem of worms is widely dealt with in another article.

Pine

It is a resinous timber with irregular grain and knots.

|

Pine tree |

For the manufacture of mouldings in recent years the “finger joint” has become the standard solution often coupled with the system of laminated wood (see the article dedicated to the finger joint and laminated wood).

An important advantage of pine compared to ayous is that the pine is not attacked by woodworms.

A problem with the framer's use of pine is the difficulty of being cut with the guillotine. In fact, the 45 ° cut made with the guillotine tends to tear the wood. In these cases it is preferable to cut the moulding with the saw.

Another problem occurs at the time of assembly. The grain of the pine tends to deflect the staples towards the inside or outside of the shaft. This problem is particularly acute for the very high and thin mouldings in which the staples are superimposed.

Wedges deviated from the wood grain

Fir

It is a wood with a fairly regular grain and with knots. Very light yellowish color.

Fir grows in mountain areas in Europe.

|

Fir tree |

The solution of finger joint and laminated wood is more and more frequently adopted for the fir.

The fir tree, unlike the ayous, is not attacked by woodworms.

As for the pine, also the fir mouldings have the problem that tend to tear when cut with the guillotine. Moreover, the superimposed staples tend to deviate following the grain.

Ramin

It is a very light timber without veins and without knots and therefore very suitable for mouldings.

Ramin trees grow in Southeast Asia (Indonesia, Malaysia, Borneo, etc.)

|

Ramin tree |

Ramin is increasingly rare because the producing states in recent years have vetoed the exploitation of forests. Also for this reasonits cost has become prohibitive.

Kotò

It is a very light wood without veins and without knots.

The tree grows throughout Western tropical Africa, especially in Cameroon and in the Ivory Coast. In recent years it has often been adopted as a substitute for the ramin.

|

Kotò tree |

Its fatures are quite similar to those of ramin.

Its main defect consists in the fact that it is attacked by woodworms even if less frequently than ayous.

Jelutong

Wood is white-yellow in color and has a fine texture and straight grain. It is often used as a substitute for ayous because it has similar features. It is not very resistant and is easily attacked by woodworms. Its use for mouldings is therefore justified only if there is a severe anti-worm treatment. It comes from Malaysia and Indonesia.

|

Jelutong tree |

Lime

It is a tree of considerable size and long life (up to 250 years or more). Sturdy trunk and wide, branchy and roundish crown.

Very common all over the world. It prefers cool and shady places.

It has a poor, very fine and smooth vein of a light cream color that sometimes tends to pale gray.

Homogeneous, light wood suitable for carving, inlay, sculpture, parts of musical instruments and for the realization of various objects. If used in the frame industry it is very easy to cut and assemble.

Finish: Takes all finishes well, best used where grain is not to become a feature. Color variation make it less suitable for clear finishes.

Not attacked by woodworms.

|

Lime tree |

Ash

The ash tree is one of the best known trees in the temperate and cold regions of the northern hemisphere. It is present in mixed forests of plains, hills and mountains up to 1500 meters above sea level.

The ash tree generally enjoys exposure in full sun or partial shade. It has a rapid and long-lasting growth: it can reach 250 years.

It has a beautiful white color with veins, is elastic and resistant, does not form splinters and does not deform.

Ash wood is widely used because it is robust and at the same time light and flexible. With the ash wood are made ski poles, propellers for airplanes, various gardening tools, handles for hammers, musical instruments and many other things that require a strong and durable wood.

Not attacked by worms.

|

Ash tree |

The “Finger Joint”

This method consists in joining several small pieces of wood to obtain long mouldings.

The advantages are:

- Knotty parts of wood, resin bags and other defective parts are discarded.

- Some parts of the wood are also used that would otherwise have to be rejected as, for example, pieces that are too short.

- Uniform mouldings of 3 meters are obtained without the limits deriving from the size of the tree.

- The mouldings obtained in this way are more rigid and do not show the distortions that are sometimes noticed on "normal" moldings.

|

Lamellar wood

Lamellar wood is produced by gluing wooden strips together.

At first the strips are obtained from the trunk, generally not more than 20 mm wide to prevent excessive deformations caused by the phenomenon of shrinkage.

Then the strips undergo a treatment to obtain stabilization in the hygrometric content.

Finally thee strips are attached to each other by hot gluing and under pressure.

They are positioned between them with opposing grain so as to ensure greater uniformity in the strength of the beam.

"Lamellar wood" systems are increasingly used in the field of picture frames.

|